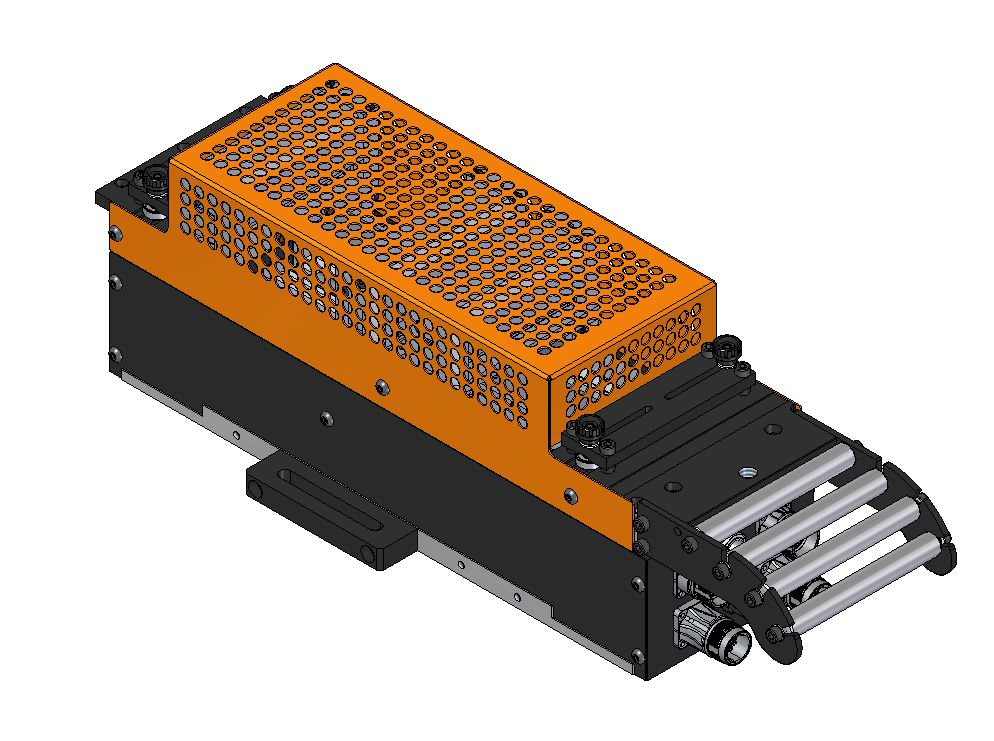

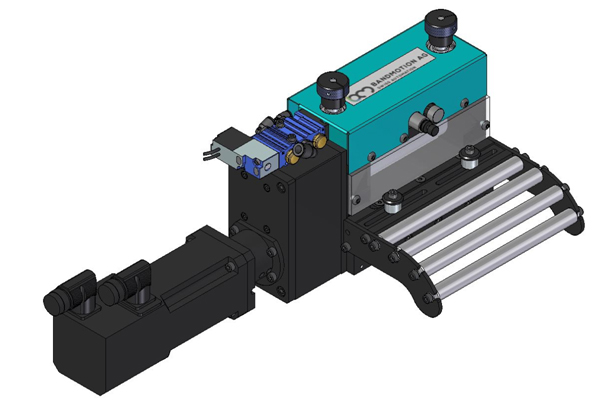

BANDMOTION AG is the new innovative force for Servo Roll- and Gripper Feeder Systems.

The company stands for Swiss Precision, Quality and Reliability.

BANDMOTION is a team of professionals with more than 25 years of expertise in developing and manufacturing high-end

Servo Feeders in Switzerland. Our innovative feeder technology is suitable to convey strip, foil and wire materials

and meets the highest customer requirements in all kind of manufacturing industries.

BANDMOTION can respond swiftly to any customer enquiry through our competent agents in Europe and Asia.

Equipped with state-of-the-art design and manufacturing equipment in our factory in Switzerland,

our team is in a position to deliver tailor-made solutions for almost any requirement.